9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

9.15 The partners of Santoku Furnace Technology Co., Ltd. embarked on a group tour of Yuntai Mountain, the staff on the road were laughing and full of expectations. Enjoy the happiness in the activity, and get the growth in the happiness!

Advantages of tilting rotary tube furnace:

1. The furnace tube motor can rotate 360 degrees, suitable for uniform sintering of mixed materials.

2. The furnace is made of various materials, such as alumina ceramic fiber board, stainless steel, quartz, etc., suitable for various material scenarios.

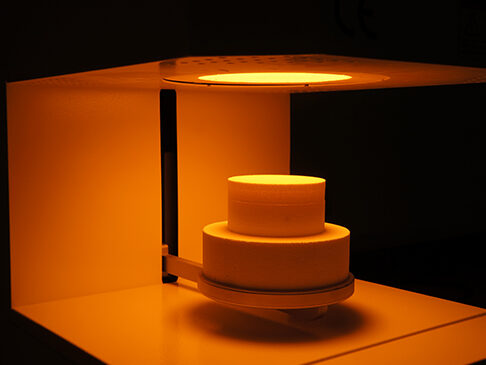

Dental Sintering furnaces play a crucial role in the sintering process of dental restorations, particularly those made from zirconia. This process transforms the milled zirconia framework into a strong, biocompatible final product. Dental sintering furnaces are used to process dental zirconia after it has been milled into a crown , bride , framework or other restoration

How to Choose Vertical Tube Furnaces?Different types of tube furnaces have their own advantages. Choosing a right tube furnace is important to your heat treatments performance.

Box furnaces are ubiquitous heat treatment components in laboratory and industrial facilities. They are widely available in floor standing and benchtop variations and are routinely used to treat single products, or individual batches, at temperatures exceeding 1200°C (2192°F). Ceramic insulation is subsequently used to improve thermal uniformity throughout the processing chamber. This offers the added benefit of limiting heat propagation through the chamber walls, which could be damaging to sensitive components.

When you are looking to buy new industrial-grade heat treatment equipment you will likely come across the terms industrial kiln, oven, and furnace. At the superficial level, these can be used synonymously. But as you get closer to the purchasing stage you will start to notice distinct commonalities and differences between these three over-generalized definitions. For example: An industrial kiln and furnace with similar specifications can be distinguished from one another purely on their intended area of application.

Submit Request