How to Set Temperature in Muffle Furnace?

A muffle furnace is a versatile and important equipment used in a variety of scientific and commercial applications, including materials testing, heat treatment, ash determination, and others. One of the most important components of running a muffle furnace is precisely establishing and controlling the temperature. Understanding how to set the temperature in a muffle furnace is critical for attaining accurate and consistent results, whether you’re a seasoned specialist or a newbie to this equipment. This article will walk you through the process of setting the temperature in a muffle furnace step by step to ensure optimal performance and precise thermal treatment.

High Temperature Heating Element Materials for Industrial Furnaces

A heating element is used to convert electricity into heat, and within an industrial furnace, there are various materials that can be used. Typically, iron-chrome aluminum or nickel chrome alloys are used in furnaces, and the standard shapes are cylindrical, semi-circular, or flat panels. This blog post will look at the other different types of materials that can be used as high-temperature heating elements.

Vertical Tube Furnaces

Definition and Design: Vertical tube furnaces are characterized by their vertically oriented heating chamber or tube. Inside the tube, the sample or material to be heated is placed and subjected to the desired temperature. These furnaces feature a heating element surrounding the tube, facilitating efficient heat transfer and ensuring uniform temperature distribution along the sample’s length.

Tube furnaces are usually operated with work tubes made from either a ceramic material such as mullite or recrystallized alumina (RCA), quartz glass, or metals, such as stainless steel or Inconel. It is vital that the work tube material is suitable for the desired application. It must be capable of withstanding the maximum operating temperature, and have appropriate chemical resistance to prevent unwanted reactions with sample materials.

From the outside, an industrial furnace looks deceptively simple, but there are many complex processes going on inside. Variations in furnace anatomy and features allow many options for heat treatment and thermal processing applications.

How to Choose Vertical Tube Furnaces?

Different types of tube furnaces have their own advantages. Choosing a right tube furnace is important to your heat treatments performance.

Important Factors Before Buying Muffle Furnace:

Different Muffle furnaces are available in the market, which you can use for various purposes & applications. However, before choosing a particular type of Lab Muffle furnace, it is essential to consider certain factors such as the temperature range, power rating, capacity, working environment, etc.

Industrial Furnaces ApplicationIndustrial furnaces can play an important role in battery research and build by providing a controlled environment for the synthesis, processing, and testing of battery materials. Here are a few ways in which industrial furnaces can assist in battery research and build

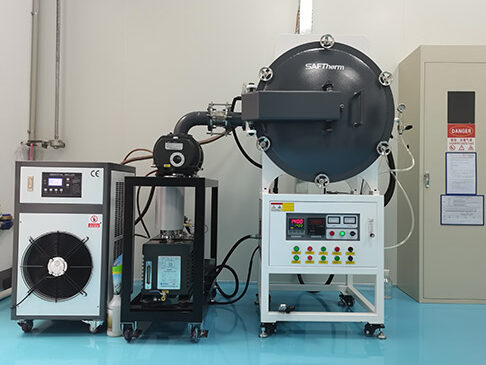

Vacuum sintering furnaces can be used for a variety of applications, including:

Medical implants : Vacuum sintering furnaces are used in the production of medical implants to achieve superior product quality and biocompatibility. The vacuum environment prevents oxidation and contamination of the powder particles, which can lead to defects in the final sintered implant.

Submit Request